Our Products

Ferro AlloyYour source for IRON ALLOY

Ferro alloys are a group of alloys that contain iron as their primary constituent and one or more other elements such as silicon, manganese, chromium, or nickel. They are typically used in the production of steel and other ferrous alloys to improve their properties, such as strength, hardness, and corrosion resistance.

Ferro alloys are added to the molten metal during the steelmaking process to improve the quality and properties of the final product. For example, ferro silicon is used for deoxidation to improve the strength and ductility of steel, while ferro manganese is used to increase its hardness and wear resistance. Other ferro alloys, such as ferro chrome and ferro tungsten, are used to improve the corrosion resistance and high-temperature properties of steel.

In addition to their use in the steel industry, ferro alloys are also used in other applications. For example, ferro silicon is used as a raw material in the production of silicone, a material that is used in a wide range of products, including electronics, automotive parts, and medical devices.

Ferro Alloys

can be provided as bulk ferroalloys under spot or long-term, fixed-price supply contracts from reputable producers. We can arrange warehousing near customers’ sites and re-pack material to ensure just-in-time deliveries.

Noble Alloys

We source several noble ferroalloys from certified producers and traders. We offer long-term, fixed-price supply contracts in combination with other services, such as tailor-made packing, crushing to size, financing of inventory, etc.

Other Alloys

In addition to the Bulk and Noble Ferroalloys, several other products do not fit one or the other category. Among them are Ferro Boron and Ferro Phosphorous, which we can offer on a spot or long-term, fixed-price basis.

Bulk Ferro Alloys

Ferroalloys are a group of iron alloys that contain a high percentage of one or more nonferrous metals as alloying elements. These alloys are brittle and unsuitable for direct use in fabricating products, but they are valuable sources of these elements for alloying steel. They improve properties like strength, ductility, and fatigue or corrosion resistance.

The principal ferroalloys are chromium, manganese, and silicon. Chromium provides corrosion resistance to stainless steel. Manganese is essential to counteract the harmful effects of sulfur in the production of virtually all steel and cast iron.

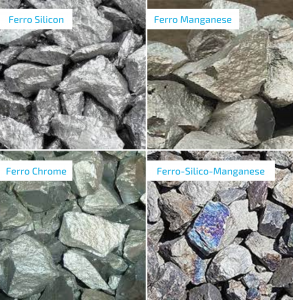

Bulk Ferro Alloys from our reputable producers:

FERRO SILICON 75

LOW CARBON/MEDIUM CARBON and HIGH CARBON FERRO MANGANESE

FERRO CHROME

FERRO-SILICO-MANGANESE

Noble Alloys

Noble alloys have a noble metal content of at least 25%. The term ‘noble’ applies as the products have outstanding resistance to corrosion and oxidation in any environment.

Noble Alloys include FeV, FeTi, FeNb, FeW, and FeMo.

FERRO VANADIUM (FeV)

Combining iron and vanadium with a 35–85% vanadium content range produces ferrovanadium alloy. FeV is commonly used in iron and steel production, particularly for high-strength, low-alloy (HSLA) steel, tool steels, and other ferrous-based products. It is a universal hardener, strengthener, and anti-corrosive additive.

FERRO TITANIUM (FeTi)

Ferrotitanium is usually produced by induction melting of titanium sponge and scrap with iron or steel. However, it is also made directly from titanium mineral concentrates. The standard grades of ferrotitanium are 30% and 70% Ti.

Stainless steel makers use Ferro Titanium as a stabilizer to prevent chromium carbide from forming at grain boundaries and in producing low-carbon steel for sheet production.

FERRO NIOBIUM (FeNb)

Ferroniobium is a vital iron-niobium alloy in making high-strength, low-alloy (HSLA) steel. FeNb is the leading source of niobium alloying. Typically, FeNb has a niobium content of 60-70%. Niobium is significantly mined and processed in Brazil and Canada.

Ferro Tungsten (FeW)

Ferro Molybdenum is an essential alloy with a 60-75% molybdenum content. Molybdenum-alloyed steels gain significantly in hardness, toughness, and corrosion resistance even with small additions of FeMo.

Ferro Molybdenum is used in various steels, such as alloyed structural steels, tool & high-speed steels, stainless steels, superalloys, and steel casting.

Ferro Molybdenum (FeMo)

Ferro Molybdenum is an important alloy with a molybdenum content of 60-75%. Molybdenum-alloyed steels gain significantly in hardness, toughness, and corrosion resistance even with small additions of Mo.

Ferro Molybdenum is used in a variety of steels, such as alloyed structural steels, tool & high-speed steels, stainless steels, superalloys, and steel casting.

Other Ferro Alloys

These products do not fit Bulk or Noble Alloys and are the other Ferro Alloys we offer:

FERRO BORON (FeB)

FeB is an alloy that contains iron and boron as its primary constituents, typically with about 17 – 20% Boron. It is a grey metallic substance with a high melting point.

FeB increases the hardness, improves the hot workability and creep resistance, and improves the wear and corrosion resistance. FeB is used in steel production.

Ferro Boron is also used to produce permanent magnets used in various electronic and mechanical devices. It is also used as a coating material for welding rods, as it helps to improve the weld bonding between the rod and the metal.

FERRO PHOSPEROUS (FeP)

FeP is an alloy of iron and phosphorous, typically with a P content of 23 – 32%. In metallurgy, it is a source of phosphorus for alloying, deoxidizing the melt, and removal of unwanted compounds.

SPEAK TO OUR EXPERTS

OUR RANGE OF PRODUCTS