Our Products

Minor metalsWe have an extensive range of Minor metals

Minor metals are a group of metals that are relatively scarce compared to more abundant metals like iron, aluminum, and copper. These metals are often used in small quantities for specialized applications in various industries, including electronics, energy, aerospace, and medical devices.

Leading Supplier

Minor Metals

Minor metals are generally by-products of smelting base metal and are not traded on the London Metal Exchange.

Antimony

Antimony is a chemical element with the symbol Sb and atomic number 51. It is a brittle, silvery-white semi-metal widely used in various industrial applications. Antimony is primarily used as a hardening agent in alloys such as pewter, lead, and copper. It is also used in the manufacturing of storage batteries, semiconductors, and flame retardants for plastics, textiles, and other materials. Antimony compounds are used as pigments in paints and ceramics and as a catalyst in the production of polyester. High purity antimony is used in the MBE (Molecular-Beam Epitaxy) process, the production of III/V-semiconductors (Indium Antimonide (InSb)) , and as a dopant for n-conducting silicon single crystals. Antimony trioxide is used as a flame retardant, while antimony oxide is used as a white pigment. Antimony’s high melting point and hardness make it useful in the production of brake pads and clutch plates, lead-acid batteries and bullets and other ammunition.

Antimony is a chemical element with the symbol Sb and atomic number 51. It is a brittle, silvery-white semi-metal widely used in various industrial applications. Antimony is primarily used as a hardening agent in alloys such as pewter, lead, and copper. It is also used in the manufacturing of storage batteries, semiconductors, and flame retardants for plastics, textiles, and other materials. Antimony compounds are used as pigments in paints and ceramics and as a catalyst in the production of polyester. High purity antimony is used in the MBE (Molecular-Beam Epitaxy) process, the production of III/V-semiconductors (Indium Antimonide (InSb)) , and as a dopant for n-conducting silicon single crystals. Antimony trioxide is used as a flame retardant, while antimony oxide is used as a white pigment. Antimony’s high melting point and hardness make it useful in the production of brake pads and clutch plates, lead-acid batteries and bullets and other ammunition.

Antimony Metal

High Purity Antimony – 99.999% (5N)

High Purity Antimony – 99.9999% (6N)

Ultra High Purity Antimony – 99.999995% (7N5) MBE (Molecular Beam Epitaxy)

Antimony Compound

High Purity Antimony Trichloride – 99.999% (5N)

Arsenic

Arsenic is 20th in ranking as the most abundant component of the Earth’s crust. It is widely available in a natural waterway, soil and in small amounts in most living things. It is a metalloid in character; in that it can be either in a metal form or a nonmetal. Arsenic is found rarely as a pure metal but is found as a component of minerals containing sulphur, the most common of which is arsenopyrite. Arsenic may also be a byproduct from mining copper, gold, and lead smelter flue dust and roasting arsenopyrite, Arsenic’s most abundant ore mineral. Commercially, Arsenic is mainly produced as arsenic trioxide or as a pure metal.

Current and historical uses of Arsenic and its compounds include pharmaceuticals, wood preservatives, agricultural chemicals, and applications in mining, metallurgical, electronics, optoelectronics, and glassmaking.

High-purity Arsenic (99.999% to 99.99999% pure) is used mainly in the semiconductor industry and to make infrared lenses.

Arsenic Metal

Arsenic is a substance found in the environment where it occurs naturally in crushed rock. Commonly bound with other elements, Arsenic is a byproduct of mining, particularly gold. Pure Arsenic is rare. The primary Arsenic source is China, from mining until the early 2000s. Now it is recovered as a byproduct of gold refining.

Current and historical uses of Arsenic include pharmaceuticals, wood preservatives, and agricultural chemicals, as well as applications in the mining, metallurgical, glassmaking, and semiconductor industries. We source arsenic metal and arsenic trioxide from established producers in China. Typically, Chinese producers offer a primary commercial grade with a minimum 99.0% Arsenic content, which is also the raw material for high-purity Arsenic. Because of its toxicity, we prefer plant-to-plant shipments; however, we can arrange warehousing at select locations in North America and Europe.

Arsenic Trioxide

Arsenic trioxide waste is also a byproduct of gold mining operations. Roasted Arsenopyrite ore releases the gold while releasing arsenic dioxide gas. As the gas cools, it changes to a solid state and becomes arsenic trioxide dust.

The main industrial application is still in wood protection treatment and some minor use in glass making and pharmaceuticals.

High Purity Arsenic

We are the North American sales agent for the high-purity arsenic producer PPM Reinstmetalle Osterwieck GmbH. The primary use of high-purity Arsenic (6N – 7N purity) is to produce gallium arsenide semiconductor crystals. Gallium Arsenide is used to make integrated circuits (power amplifiers in cell phones, radar technology, wireless devices, etc.) and to manufacture light-emitting and laser diodes. Molecular beam epitaxy applications use the highest purity arsenic (7N+).

Arsenic 5N and/or 6N pure is used to produce Arsenic Triselenide, used to make photocopier drums, and chalcogenide glass used to make infrared transmitting lenses. In everyday life, you will find high-purity Arsenic in your cell phones, wireless base stations, chargers, IR cameras, and cars.

High Purity Arsenic – 99.9995% (5N)

Ultra High Purity Arsenic – 99.9999% (6N)

Ultra High Purity Arsenic – 99.99999% (7N)

Ultra High Purity Arsenic – 99.99999+% MBE (7N+)

Cadmium

Cadmium (Cd) is a bluish-white metal used in a range of industrial applications due to its low melting point and high resistance to corrosion. One of the primary uses of cadmium is in rechargeable batteries, including nickel-cadmium batteries, where it serves as the negative electrode. Cadmium is also used in electroplating and the production of various alloys, such as those used in bearings and other mechanical components. Additionally, cadmium is used in the production of pigments for paints and coatings, and in some types of nuclear reactors as a neutron absorber. However, due to its toxic nature, cadmium’s use in batteries is being phased out in favor of safer and more environmentally friendly materials.

Calcium

CALCIUM METAL AND ALLOYS

Calcium is an alkaline mineral found in teeth, shells, bones, minerals, and rocks. Calcium carbonate occurs compound that is the basis for limestone, marble, and chalk. Calcium is a soft metal (silvery-white) that tarnishes rapidly in the air and reacts with water. Calcium chemically resembles strontium and barium; it is classed with them as an alkaline-earth metal in Group 2 of the periodic table.

It is a reducing agent to prepare other metals such as thorium and uranium. It is also an alloying agent for aluminum, beryllium, copper, lead, and magnesium alloys. Calcium is added to steel during manufacture for the reduction of sulphur (desulfurizer) and oxygen (deoxidizer) contents and to control the shape of remaining sulfide inclusions.

Calcium will react with water or moisture causing heat and may form flammable and explosive hydrogen gas. Contact with the skin will cause irritation and possible corrosion damage.

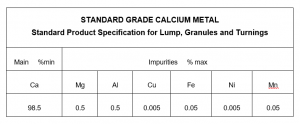

Standard Product Specification for Lump, Granules and Turnings (click image for the full-size)

Material Sizing

Lumps in size 30 – 200 mm or produced to order

Granules are available in sizes 0 – 2 mm, 0.4 – 2.0 mm, 0.4 – 1.7 mm or produced to order

Turnings in size L 30 – 70 mm, W 6 – 8 mm, and T 0.7 – 3.6 mm

Packing:

Lumps are sealed in double-layer poly bags under argon gas, packed in UN-approved steel drums, 125 kg net weight per drum with 4 drums per pallet @ 500 kg net weight

Granules are sealed in double-layer poly bags under argon, packed in UN-approved steel drums, 175 kg net weight per drum with 4 drums per pallet @ 700 kg net weight

Turnings are sealed in double-layer poly bags under argon gas, packed in UN-approved steel drums with 80 kg net weight per drum, 4 drums per pallet @ 320 kg net weight

CALCIUM WIRE

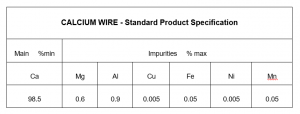

Standard Product Specification (click image for the full-size)

Diameter and Density

Calcium metal extruded wires are available in:

7.5 mm +/- 0.2 mm, at 68-73 g/m and

8.5 mm +/- 0.2 mm, at 85-90 g/m.

The plant can also produce as per the customer’s specific requirements

Packing

Extruded calcium metal wire is sealed and packed under argon gas in double-layer poly bags, packed in UN-approved steel drums with approx.175 – 185 kg net weight per drum, 4 drums per pallet @ 700 – 740 kg net weight

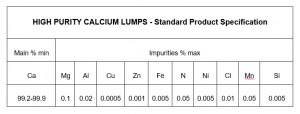

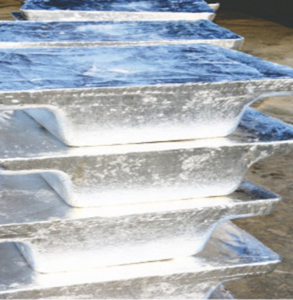

HIGH-PURITY CALCIUM LUMPS

Standard Product Specification (click image for the full-size)

Material Sizing: Lumps in size 30 – 200 mm or produced to order

Packing: High-purity calcium lumps will be sealed in a double-layer poly bag under argon gas, packed in UN-approved steel drums with 125 kg net weight per drum, 4 drums per pallet @ 500 kg net weight

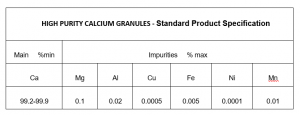

HIGH-PURITY CALCIUM GRANULES

Standard Product Specification (click image for the full-size)

Product Size: High-purity calcium granules are available in sizes 0 – 2 mm and 2 – 8 mm or produced to order

Packing: High-purity calcium granules are sealed in double-layer poly bags under argon gas, packed in UN-approved steel drums, 150 kg net weight per drum with 4 drums per pallet @ 600 kg net weight

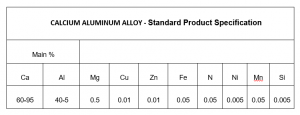

CALCIUM ALUMINUM ALLOY

Standard Product Specification (click image for the full-size)

Size: Calcium Alloy is available in 30 – 70 mm and 50 – 150 mm or produced to order

Packing: Calcium aluminum alloy lumps are sealed in argon gas-filled small poly bags of 5 or 10 kg net weight each, then packed in UN-approved steel drums with max. 160 kg net weight capacity, 4 drums per pallet with max. 640 kg net weight

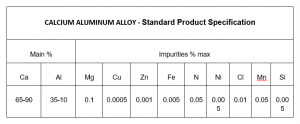

HIGH-PURITY CALCIUM ALUMINUM ALLOY

Standard Product Specification (click image for the full-size)

Size: High-purity calcium aluminum alloy lumps are available in sizes 50 – 200 mm or 50 – 150 mm or produced to order

Granules: 2-8mm

Packing: High Purity Calcium Aluminum Alloy lumps are sealed in small argon gas-filled poly bags of 5 or 10 kg net weight each, then packed in UN-approved steel drums with max. 160 kg net weight capacity, 4 drums per pallet with max. 640 kg net weight

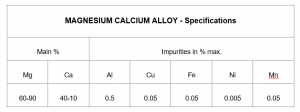

MAGNESIUM CALCIUM ALLOY

Specification (click image for the full-size)

Weight/Dimensions: Magnesium calcium alloy ingot weighing approx. 10 kg (+/- 0.5 kg) each, with L 532 mm x W 150 mm on the bottom and L 492 mm x W 115 mm on the top and a height of 88 mm. The ingots can be produced with or without two V-shaped notches.

Packing: Magnesium Calcium alloy ingots are stacked on pallets and securely tied with metal bands and shrink-wrapped, with 120 ingots per pallet @ approx. 1,200 kg net weight manufacturing.

Magnesium

Today’s world production of magnesium is dominated by China with just a few producers operating in the Western world. The primary raw material for the production of magnesium is Dolomite, which is abundantly available. Magnesium is a silvery-white, lustrous, and relatively soft metal that tarnishes slightly in air.

Today’s world production of magnesium is dominated by China with just a few producers operating in the Western world. The primary raw material for the production of magnesium is Dolomite, which is abundantly available. Magnesium is a silvery-white, lustrous, and relatively soft metal that tarnishes slightly in air.

Magnesium is the lightest of the structural metals, about 30% compared to aluminium and up to 70% compared to steel. It is one-third less dense than aluminium and improves the mechanical, fabrication and welding characteristics of aluminium when used as an alloying agent.

Magnesium has excellent shock-absorbing properties against vibration and noise. Its impact resistance is 20 times that of plastic. Magnesium has a good casting performance and like aluminum and zinc it is a strong, rigid material. Magnesium has a good strength-to-weight ratio and is corrosion-resistant, ideal for use in electronic products.

Magnesium is also used in ductile iron production to promote the nodularization of graphite and also as an alloying element in the production of magnesium-based ferroalloys. In a powder form and mixed with other materials, Magnesium is commonly used as a desulfurizer in many metallurgical applications.

PRIMARY MAGNESIUM INGOTS/T-BARS

Its main use is as an alloying metal in primary and secondary aluminum for use in automotive parts, extruded products and beverage cans. The standard purity is min. 99.9% Mg and the typical weight is around 8 kg for ingots and 125 kg for T-Bars. We source all our primary magnesium from a few select smelters in China who have been audited and quality approved by one of our major end users.

HIGH-PURITY MAGNESIUM INGOT

These ingots are produced either according to ASTM or Chinese standards with a purity of min. 99.95% Mg. The main end use is in aluminum alloying and magnesium die casting, particularly for the aerospace industry, where quality is paramount.

MAGNESIUM ALLOYS

Numerous magnesium alloys have been developed over the years for specific end uses in the automotive, aerospace, and electronic industries. The most common form is a die-cast ingot but it can also be used in granular or chip form for Thixomolding.

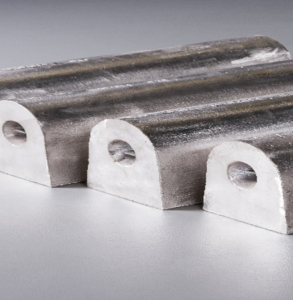

MAGNESIUM ANODES

Magnesium anodes are effective and affordable when it comes to battling corrosion. For over two decades, magnesium anodes have played a pivotal role in the protection of steel structures in salt and fresh water, including the Hulls of ships and various other boats. They are typically produced as an alloy for cathodic protection of steel structures in salt and fresh water, in hulls of ships and boats or in corrosive environments.

Selenium

William Rowland Americas is the North American distributor for RETORTE GmbH in Roethenbach, Germany. They are ISO certified and have produced various selenium metals and chemicals for over 70 years.

Selenium is a red-gray, lustrous metalloid (semi-metal). Its name comes from the Greek word Selene for “moon.” The metal was discovered in 1817 by Swedish chemistry professors Berzelius and Gahn. Selenium is not found as a pure metal, nor are there selenium ores or ore deposits. The metal is present in minor quantities in many different minerals, particularly copper, iron, and lead sulfides.

All selenium is produced as a by-product from two base metals. More than 90% comes from copper ores, and the balance mainly comes from lead ores, with a negligible amount from nickel processing. However, metal refiners process the ores and generate selenium as a by-product due to far more valuable by-products, such as gold, silver, palladium, and platinum, contained in the ore.

SELENIUM METAL POWDER

It is available in purities of min. 99.5% min, 99.8%, and min. 99.9% Se and in sizes of 100 and – 200 mesh. The standard packing is in 25 kg drums/pails with either 18, 20, or 24 drums per pallet (450/500 and 600 kg net weight). The primary end use remains for coloring/decoloring of glass, with a small percentage used in pigments.

SELENIUM METAL PELLETS

Selenium pellets are used in metallurgical applications, such as lead refining and select steel applications. Standard commercial grades are available in min. 99.5% and 99.9% purity. The pellet size ranges from 0.5 to 5.0 mm, packing in 25 kg drums/pails and 24 drums per pallet (600 kg net weight).

HIGH-PURITY SELENIUM METAL AND ALLOYS

Selenium is both photoconductive and photovoltaic, which makes it useful in high-speed printers and CI(G)S solar cells. However, using selenium in these applications and rectifiers & receptors is diminishing. There are promising developments in medical imaging and chalcogenides for HP selenium, while the traditional end use (as ZnSe) in infrared lenses continues.

RETORTE produces high-purity selenium metal and alloys in pellet form and in the following qualities:

Min. 99.995% Se

Min. 99.995% Se with low oxygen

Min. 99.998% Se

Min. 99.998% Se with low oxygen

Min. 99.999% Se

SELENIUM CHEMICALS

Selenium has dual properties and can be used as an oxidizing agent, catalyst, or deoxidizer. It finds its way as a compound into many applications and industries, such as in agriculture as a micronutrient or fertilizer, in humans and animals as an essential trace element, in metallurgy as an additive for electrolytic manganese and electroplating, in the glass industry for higher retention of Se as well as in the medical and pharmaceutical industry.

Sodium Selenite

It is available in technical, feed, and pharma grades. Its primary use is in animal feed pre-mixes, as a glass decolorizer, and in the health care, food, and pharmaceutical industries.

Sodium Selenate

It is available in technical, feed/agriculture, and FCC grades. Its main applications are as an animal feed additive, fertilizer & plant nutrients, and in the health care, food, and pharmaceutical industries.

Zinc Selenite

It is used as a coloring/decoloring agent in the glass and ceramic industry.

Selenium Dioxide

Its main application is as an additive for electrolytic manganese. It is also used in the electroplating and pharmaceutical industry

Silicon Metal

Silica found in quartz produces silicon metal through a reduction in submerged arc electrical furnaces, which could exceed 3,000 C, using charcoal and wood chips as reductants.

The basic process for producing silicon has remained unchanged for decades: high-purity quartz or gravel (SiO2) is blended with a carbon source and superheated in a submerged electric arc furnace. As the mix heats, the carbon reacts with the oxygen in the quartz and forms CO gas, thereby reducing the quartz to 99% silicon in molten form.

Silicon metal is used to manufacture more than 10,000 products, which are used in industrial production and by people in their daily lives. Its main applications are:

- Aluminum alloys

- Silicones

- Solar panels

- Refractories

- Semiconductors

We can offer silicon metal from several producers around the world in the following qualities:

Metallurgical Grade

Aluminum alloys are mainly for the automotive industry. The production of aluminum alloys needs this grade. The metal is available in various qualities and sizes; the most common grades of silicon metal are Fe/Al/Ca 4/4/1, 5/5/3, 3/3/03, and 2/2/02. In addition to these grades, some are lesser known, such as 4/2/1, 4/1/1, and 1/1/01.

Chemical/Electronic Grade

Chemical Grade Silicon Metal is the primary raw material for producing special silicones, called light oils. Light oil products have applications in medicine, cosmetics, electronics, textile, automobiles, and construction.

Micronized (High Purity) Silicon

Used in the Semiconductor Industry, Micronized Silicon is the primary raw material in the production of Trichlorosilane, which are transformed into diodes and processors of high performance (computer microchips). Polysilicon is the raw material used to make solar cells for a growing market worldwide as an alternative for a new energy matrix.

Chemical Specification (click image for the full-size)

![]()

Tellurium

Tellurium is a chemical element, a chalcogen, with the symbol Te and atomic number 52. It is a metalloid, meaning it has properties of both metals and nonmetals. Tellurium is a rare element, found only in small amounts in the Earth’s crust.

Tellurium has several important industrial applications. One of its primary uses is in the production of alloys, particularly in the production of steel and copper. Tellurium can improve the machinability and strength of these metals, and can also make them more resistant to corrosion.

Tellurium is also used in the production of solar panels, where it is used as a semiconductor material. Additionally, tellurium is used in the production of thermoelectric materials, which convert heat into electricity.

Tellurium is also used in the production of a variety of other products, including blasting caps, vulcanizing agents, and pigments for ceramics and glass. It is sometimes used as a coloring agent in glass to produce a red or pink tint. Additionally, tellurium dioxide is used in the production of optical lenses and other optical components. Overall, the unique properties of tellurium make it a valuable material in a variety of industrial applications.

SPEAK TO OUR EXPERTS

OUR RANGE OF PRODUCTS